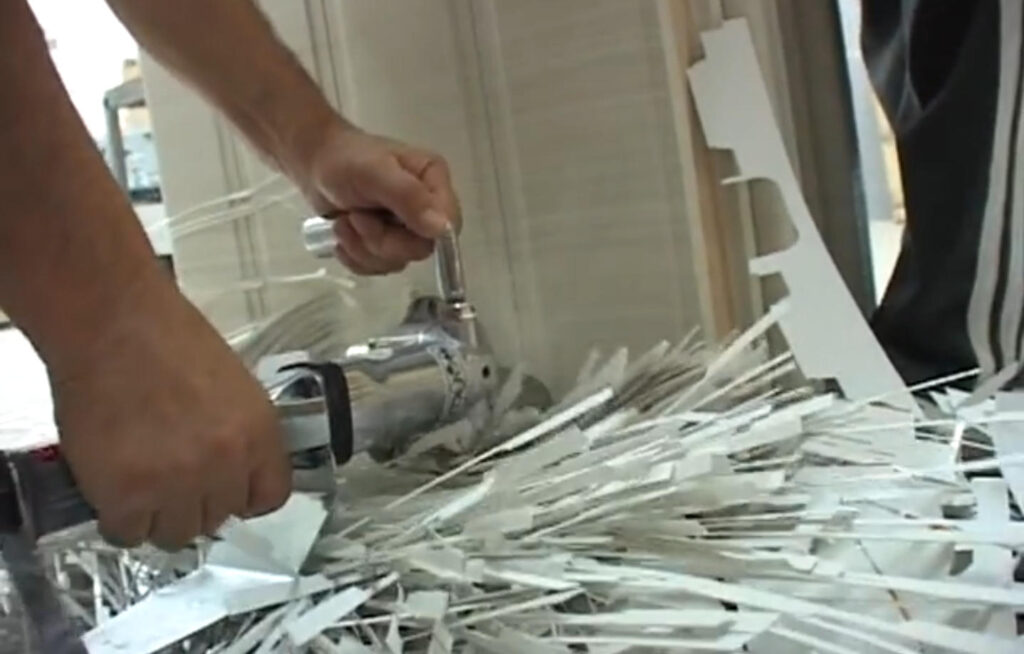

In many packaging factories, the real bottleneck is not die-cutting speed, but what happens after. Waste stripping is still handled by hand in many plants. It looks simple, but it slows output, increases labor pressure, and prevents the post-press line from running smoothly. When volumes grow, this single step often limits the entire workflow.

Manual waste stripping can be replaced by mechanical solutions, either through inline stripping on the die-cutter or by using an independent offline blanking machine.

Inline stripping requires stable layouts and controlled die-cut quality, while offline blanking removes stripping from manual work without changing the existing die-cut process.

The real issue is not whether mechanical stripping works. It clearly does.

The real issue is where it belongs in your workflow. In real factories, different order mixes, die-cut accuracy levels, and labor structures lead to very different results. This is why the same solution performs well in one plant and fails in another. To make the right decision, you need to understand how manual stripping creates hidden risk, how each mechanical option behaves on the shop floor, and which jobs should—or should not—be automated.

Why manual stripping becomes a long-term production risk

Manual stripping depends on people, not systems.

Speed changes by operator. Quality changes by shift.

As order volume increases, you add workers, not capacity. Training takes time. Turnover creates gaps. Even when die-cutting runs fast, finished sheets wait for stripping.

Over time, the cost shows up as unstable delivery and uneven quality. Planning becomes reactive. The die-cut section cannot run continuously.

Two mechanical paths to replace manual stripping

Mechanical stripping is not one solution. There are two clear paths, and they serve different factory conditions.

Inline stripping on the die-cutter

Inline stripping removes waste during the die-cutting cycle.

It is fast, but strict.

This option works best when:

- Box layout stays consistent

- Orders repeat regularly

- Die-cut accuracy is stable

- Tooling and setup are well controlled

If layouts change often or die-cut quality fluctuates, inline stripping causes stops instead of speed.

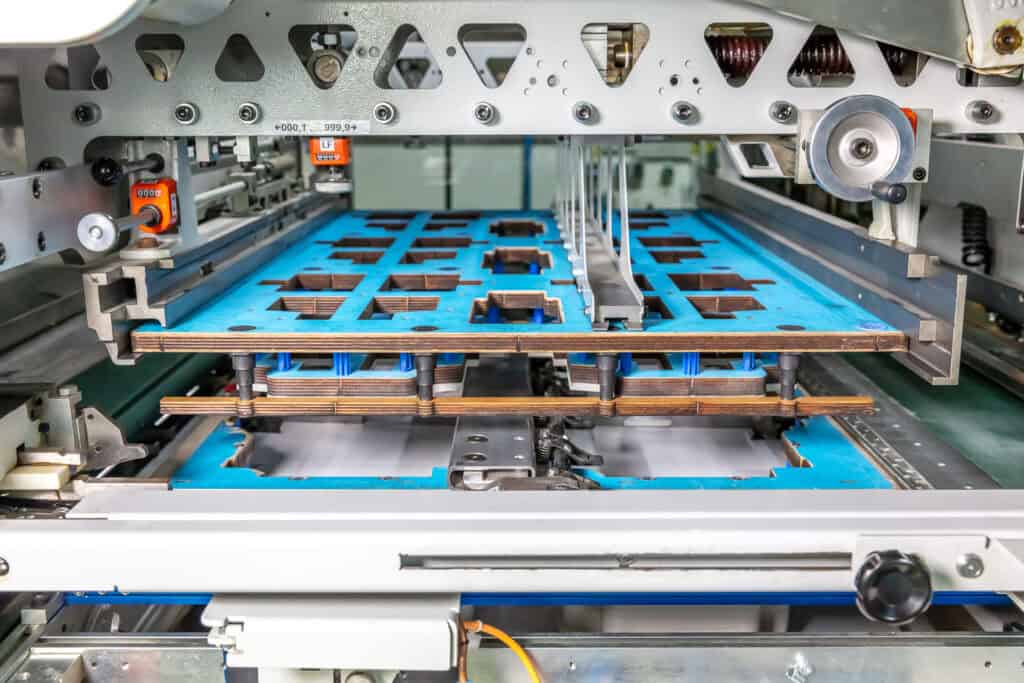

Offline blanking machines

Offline blanking separates stripping from die-cutting.

Sheets are stacked, then processed independently.

This approach fits factories that:

- Run mixed or flexible orders

- Want to reduce labor without rebuilding lines

- Need stripping stability without touching die-cut speed

The key advantage is isolation. Problems in stripping do not stop die-cutting.

Which jobs should not be automated

Not every order benefits from mechanical stripping.

Automation struggles when:

- Layouts change daily

- Waste bridges are inconsistent

- Sheet quality varies

- Quantities are too small to justify setup

In these cases, controlled manual stripping may still be the safer choice.

Automation should remove risk, not introduce it.

Why “more automation” is not the goal

Many factories focus on machine price.

That is the wrong metric.

Real savings come from:

- Stable output per shift

- Fewer people needed to maintain speed

- Predictable delivery over many years

Mechanical stripping is a workflow decision.

It affects die design, stacking, feeding, and downstream folding and gluing.

A practical upgrade path most factories follow

Very few plants jump directly to full automation.

A common path looks like this:

- Standardize manual stripping

- Introduce offline blanking to reduce labor pressure

- Apply inline stripping for stable, repeat products

This sequence limits risk and protects existing investment.

Summary

Mechanical stripping is not about replacing people with machines.

It is about deciding where stability should come from—experience or systems.

Factories that make this decision carefully do not just strip waste faster.

They run calmer lines, plan with confidence, and grow without adding pressure at every step.