Paper processing is an important industry in packaging, enterprises need to use efficient, stable, and safe mechanical equipment to improve production efficiency and product quality. Among these devices, Paper blanking machine for removing waste widely used. There are mainly two types of blanking machine on the market: Auto waste stripping machine and hand-held Pneumatic Waste Stripper. This article will focus on What’s the advantage of each?

The difference between these two types

Auto waste stripping machine and Pneumatic Waste Stripper are two common types of paper processing equipment. The main differences between the two are as follows:

Definition:

auto waste stripping machine is a kind of equipment operated by automatic control system. A Pneumatic Waste Stripper is a device that operates using a semi-auto pneumatic control system.

Working principle:

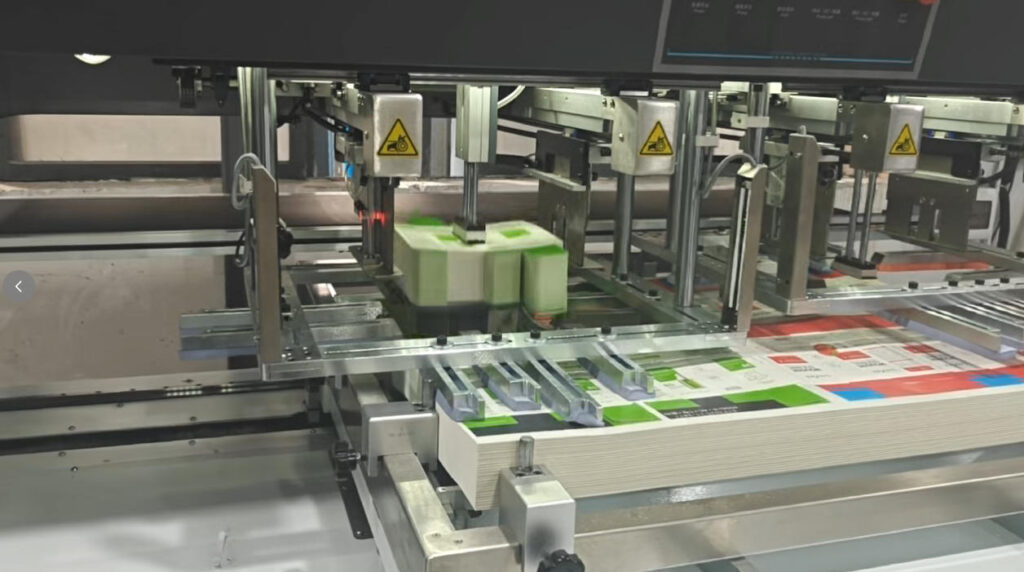

Through computer control, the automatic waste blanking machine can not only automatically detect and locate the paper, but also push out the finished products from the whole sheet, so the entire operation process has a high degree of automation. The Pneumatic Waste Stripper need to operate by Pneumatic system with entire tedious operation process.

Comparison of advantages and disadvantages:

The positioning accuracy of the auto waste stripping machine is high, while the pneumatic waste stripper can only manually position.

The auto waste stripping machine are simple to operate and no physical requirements, whereas pneumatic stripper require a certain level of stamina since it needed to be held by labors while working.

The high productivity of auto waste stripping machine meets the needs of high-volume, high-quality production, while the productivity of pneumatic stripper is relatively low.

Advantages of auto waste Stripper machine

The following significant advantages:

High production efficiency:

Fully automatic operation without human intervention, greatly improving production efficiency.

Better quality control:

using computer control, high-precision cutting, effective control of product quality.

Simpler operation:

Simple operation, the operator only needs to carry out simple equipment commissioning and program settings.

More secure: No manual intervention required, effectively avoiding operator injuries during operation.

Application Range of auto waste Stripping machine

Applicable to the following situations:

Suitable for producing multi-variety, small-batch, high-quality paper products: it can efficiently and accurately remove waste from different types of paper.

Suitable for situations with low technical requirements for operators: it’s easy for operators to carry out simple equipment debugging and program settings.

Maintenance of auto waste Stripper machine

Significance of equipment maintenance: Need to perform regular maintenance and upkeep on the equipment in order to ensure normal machine operation. The main point of equipment maintenance is to prolong equipment life, reduce equipment failures, improve production efficiency, and ensure product quality.

Maintenance methods for machines include the following:

- Regularly clean equipment: It not only effectively removes dust and debris from the surface of the equipment, but also reduces the occurrence of equipment failure.

- Regular checking on equipment: This allows problems to be identified, repaired and replaced in a timely manner to avoid equipment failure affecting production.

- Regular Adding Lubricant: Add lubricant after equipment running to ensure the normal operation of the equipment.

Conclusion

The automatic stripping machine has many advantages such as high production efficiency, better quality control, simpler operation, and more safety. It is suitable for the situation of multi-species, small batch, high quality production, high requirements for the working environment, low technical requirements for operators and other occasions. In the use of automatic waste stripping machine need to pay attention to maintenance and other issues to ensure that the normal operation of the equipment, reduce the occurrence of equipment failure.

SINHOSUN, as a professional manufacturer of waste stripping machines, has launched various types of waste stripping machines to meet the needs of different customers. If you want to learn more information, Please hurry up to contact us.